Gentle cleaning

Removes oxidation and grime while keeping edges crisp.

Removes oxidation and grime while keeping edges crisp.

That “factory fresh” look people pay for in restoration.

Perfect baseline finish before assembly, coating, or detailing.

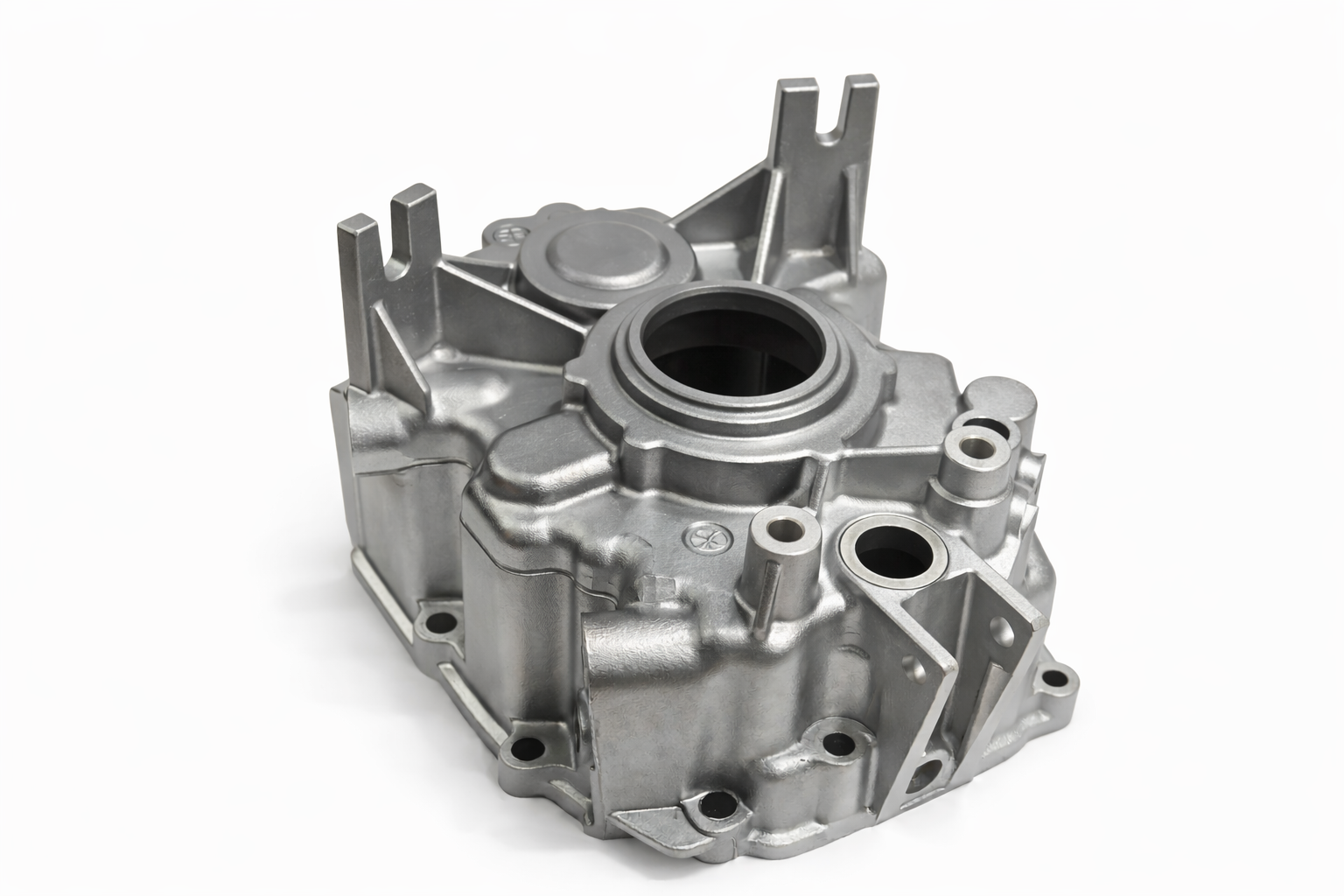

Aluminum, steel, cast components — automotive, moto, CNC.

Yes, absolutely. Paint, powder coat, and Cerakote can be removed.

Depending on coating type and thickness, we use dry sandblasting, stripping, or a combination of processes before vapor blasting.

This ensures the coating is fully removed and the surface is properly prepared for a uniform, factory-correct satin finish.

Yes. Steel parts can be fully restored and significantly improved.

We use a combination of dry sandblasting and vapor blasting to remove rust, old coatings, and surface contamination, then refine the surface to a clean, uniform, professional-grade result.

This process is ideal for restoring steel parts and preparing them for coating, painting, or assembly, with consistent and controlled surface quality.

Almost never — and intentionally so.

We stand behind our results and guarantee that no abrasive remains in oil passages, bores, or critical areas. With assembled parts, that level of control cannot be guaranteed.

For this reason, parts must be fully disassembled before blasting. When needed, we can handle disassembly in-house, including removing bearings, seals, studs, and pressed-in components, to ensure the part is properly prepared and safely restored.

Yes — heavy rust can be removed.

We use the appropriate combination of dry sandblasting and vapor blasting to fully remove corrosion and reveal clean base metal.

It’s important to understand that while rust can be eliminated, deep pitting is missing material and cannot be reversed. Our process focuses on proper rust removal, surface refinement, and preparing the part for restoration, coating, or assembly with a clean, uniform result.

No — when done correctly, our process is focused on surface restoration, not material removal.

We control media type, pressure, and technique to clean and refine surfaces without altering critical dimensions or tolerances.

Sensitive areas can be masked or treated separately, ensuring the part retains its original geometry while achieving a factory-correct, uniform finish.